In the modern era of advanced technology and complex electrical systems, the demand for efficient and reliable connectivity is more critical than ever. Customized cable assemblies—specialized configurations of cables and connectors designed to meet specific requirements—play a vital role in ensuring optimal performance across various industries. Unlike standard off-the-shelf cables, custom cable assemblies are tailored to meet the unique electrical, mechanical, and environmental needs of a specific application. This essay explores the key benefits of customized cable assembly, including enhanced performance, improved efficiency, cost-effectiveness, reliability, and design flexibility.

1. Enhanced Performance and Compatibility

Customized cable assemblies are designed with the precise specifications of the application in mind, which ensures optimal compatibility and performance. For example, in industries like medical technology, aerospace, and automotive manufacturing, where precision and reliability are paramount, custom cables can be engineered to accommodate unique voltage requirements, signal transmission speeds, and environmental conditions. This tailored approach helps eliminate interference, reduce signal loss, and ensure consistent performance over time.

2. Improved Efficiency in Installation and Maintenance

One significant advantage of customized cable assemblies is the ease of installation and maintenance. When cables are built to exact lengths with specific connectors and labeling, the assembly process becomes more straightforward and less time-consuming. This reduces the likelihood of errors during installation and helps technicians identify and replace faulty components quickly. Additionally, pre-assembled, plug-and-play cable configurations can streamline the wiring process, improving overall operational efficiency.

3. Cost-Effectiveness in the Long Term

While customized cable assemblies may have a higher upfront cost compared to generic cables, they often result in long-term cost savings. Custom cables reduce the need for excess inventory, minimize waste, and eliminate the costs associated with modifying standard cables to fit particular applications. Moreover, their durability and high-quality construction often lead to fewer failures, lowering repair and replacement costs over time.

4. Increased Reliability and Durability

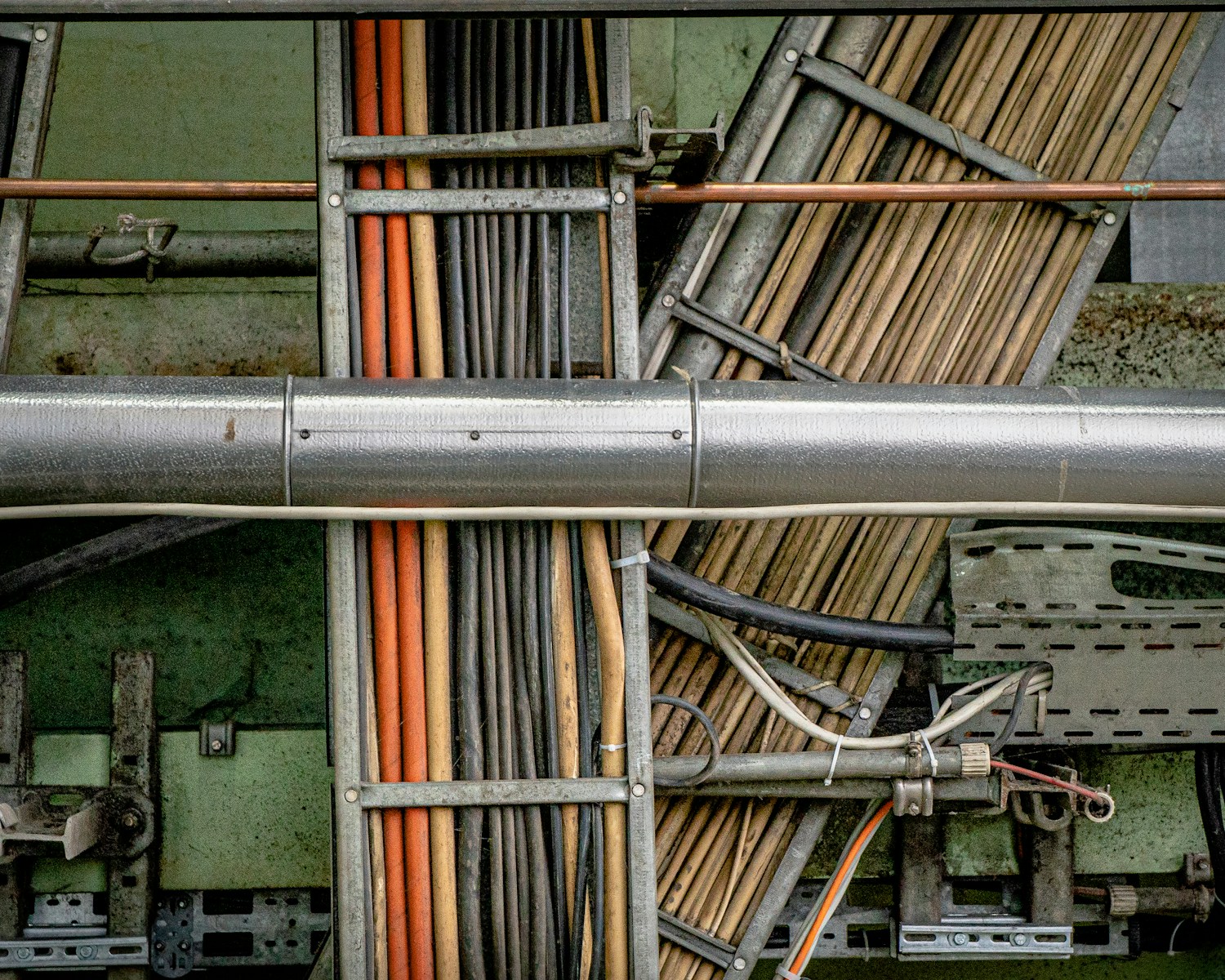

Custom cable assemblies are typically manufactured using high-quality materials that are selected based on the specific environmental and mechanical stresses the cables will face. This attention to detail results in cables that are more robust and reliable, especially in harsh environments such as extreme temperatures, moisture, chemicals, or mechanical abrasion. By reducing the risk of electrical failure, customized assemblies help enhance system uptime and safety.

5. Design Flexibility and Scalability

Another important benefit of customized cable assembly is design flexibility. Engineers and manufacturers can work with cable assembly specialists to create solutions that fit within tight spaces or meet unique design requirements. This flexibility is especially beneficial in modern electronics, where compact and lightweight designs are essential. Furthermore, custom cable solutions can be scaled up or adapted as product lines evolve, ensuring long-term compatibility with future technological developments.

Conclusion

Customized cable assemblies offer a range of benefits that go beyond what standard cables can provide. By delivering enhanced performance, ease of installation, cost savings, improved reliability, and flexible design options, they represent a strategic investment for industries that depend on high-performance electrical systems. As technology continues to evolve, the need for tailored cable solutions will only grow, reinforcing the importance of customization in achieving optimal connectivity and functionality.